Canary Media Interview With Dr. Lonnie Johnson

This Billion-dollar-selling Toy was Inspired by Heat Pumps!

By Mike Munsell for Canary Media

This fun fact was recently discussed at a Canary all-hands meeting. I was out of the office at the time, completing my family’s winter BINGO card (stomach Bug, INfluenza, Gastro issues, cOvid), but given my writings on the heat pump’s uncanny resemblance to George Clooney and the debate over its nomenclature, the team decided I was best suited to investigate this intriguing connection.

Before we get to that story, I’d like to tell you a little bit about the inventor of the Super Soaker himself, Lonnie Johnson, because his resume is pretty incredible.

Here are just a few of his accolades:

- Master’s degree in nuclear engineering

- U.S. Air Force engineer who worked on the B-2 “stealth” bomber program

- NASA systems engineer for both the Galileo mission to Jupiter and the Cassini mission to Saturn

- Inventor of the Super Soaker water gun

- Inventor of the Nerf N-Strike dart gun

- National Inventors Hall of Fame inductee

I chatted with Johnson last week to hear firsthand what heat pumps had to do with the invention of the Super Soaker and to learn more about some of his current work, including the solid-state battery storage company he founded.

But first, I asked Johnson to tell me the story of how he invented the Super Soaker, and he obliged, even though it’s clearly one he’s told hundreds, if not thousands, of times.

It was 1982, and during his off hours from his day job as an engineer at NASA’s Jet Propulsion Laboratory, he could often be found at home tinkering and inventing. His pet project at the time was developing a more environmentally friendly heat pump — one that used water in place of Freon. Johnson explained to me that he wanted to put the high water pressure that comes into homes to use as a power source.

Johnson, a literal rocket scientist, explained to me how this water-based heat pump would work.

“So the idea was for water to come through a nozzle, so that when the water vapor flash evaporates into a low-pressure region, that evaporation process will drop the temperature of the water. When the water temperature is cool, you can transfer heat to it. Then at the bottom, you would recondense the water, but at a higher temperature.”

I, not a rocket scientist, nodded along.

“So I was experimenting with some nozzles,” continued Johnson, “and I had a nozzle I made in my shop hooked up to the bathroom sink, and I shot the stream of water across the bathroom, and I thought as a toy, it would be a lot more fun.”

After some iterations, Lonnie eventually assembled the original Super Soaker prototype, made of an empty soda bottle, PVC pipe, O-rings and nylon tubing. It would be almost a decade before the prototype became the billion-dollar blockbuster toy we know today.

Over the decades since its launch, Johnson has earned millions of dollars from the Super Soaker and Nerf guns. Most people might be tempted into early retirement, but not Lonnie Johnson.

“I thought that I could earn enough money from a toy to support myself and then go back to some of the more challenging projects,” he told me about first inventing the Super Soaker. “And basically, that’s what I’ve done.”

While Johnson was happy to recount this tale, he was much more excited to tell me about those “more challenging projects” that he is working on now with his two companies JTEC Energy and Johnson Energy Storage, both based in Atlanta, Georgia.

Below is an edited and condensed transcript of the remainder of our conversation.

Mike Munsell: Can you tell me about JTEC Energy?

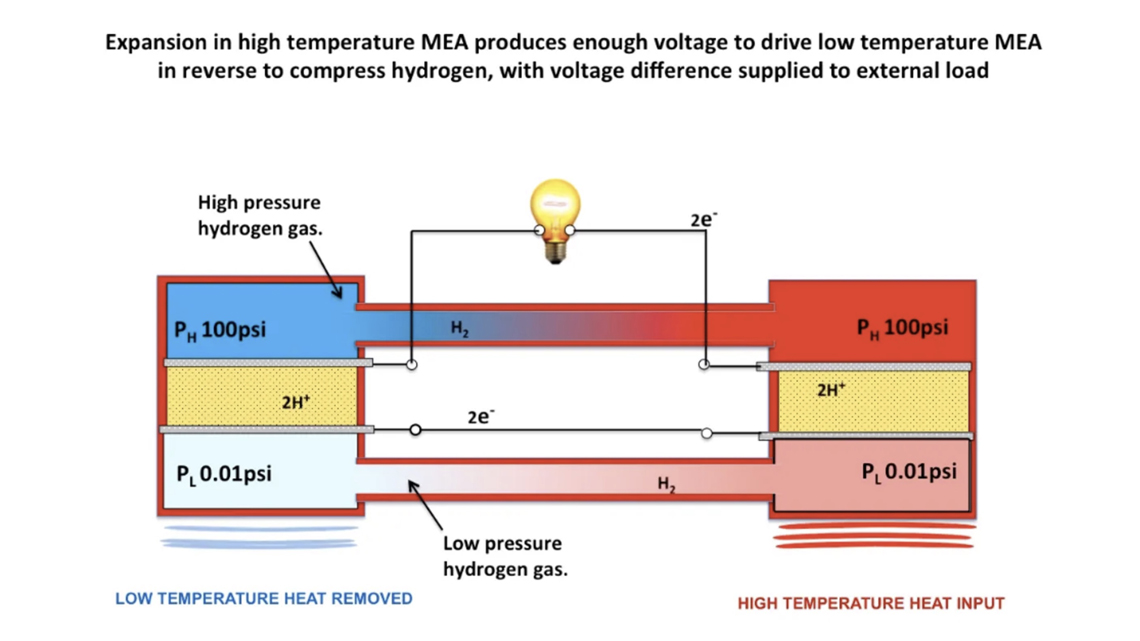

Lonnie Johnson: What we’re working on now is called a Johnson thermoelectric energy converter (JTEC), and it converts heat directly into electricity. Instead of using water as a working fluid, it uses hydrogen. But the really neat thing about it is that it has no moving mechanical parts — it’s all solid-state.

The other neat thing about the JTEC technology is that it can operate on low-grade waste heat. The low-temperature range of 100–200 degrees Celsius is where there’s an abundance of waste heat from various industrial processes — even our power plants reject heat at around 100 degrees or so. There’s not a technology that can cost-effectively convert that waste heat into electrical power. And so that’s the capability that we bring to the table with a JTEC.

Munsell: So what are the use cases you’re looking at for JTEC?

Johnson: The primary use case that we’re focused on is geothermal. We’re in the middle of constructing a 250-kilowatt demonstration unit now. This would be the first time we really scale the technology out. We’ve done laboratory demonstrations and so forth. But the primary application will be thermal heat.

There is an abundance of abandoned oil wells around the country and the world. And they all have geothermal heat down in the range of 100 to 200 degrees Celsius. That temperature is too low for conventional techniques for converting heat to work, but JTEC can convert that heat to electricity directly and do it more efficiently. And our projections indicate that it would be very cost-effective. It turns out that [using JTEC on] just 20% of the abandoned oil wells in the country could meet all of the U.S.’ power requirements. So we’re very excited about it, to say the least.

Munsell: And you also run a solid-state battery storage company, right?

Johnson: The energy storage company is called Johnson Energy Storage. We’ve done our seed round of investors — we raised a few million dollars.

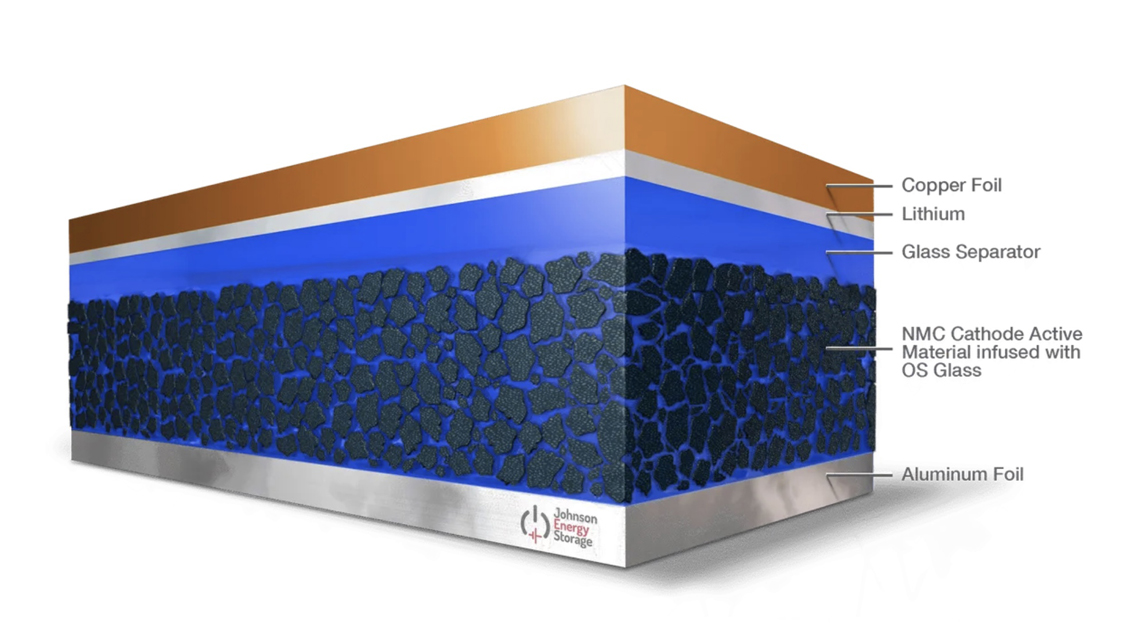

I would venture to say that we are one of two, maybe three true solid-state battery companies in the world. People claim they have solid-state, but they’re using polymer gel, electrolytes and so forth. Our system is all ceramic, glass and metal materials. We literally have developed a glass electrolyte that will meet the performance requirements of the auto industry. We’re in the process of demonstrating that right now. We’re basically transitioning the technology out of the lab, making small cells that we can sample to customers so that they can see, indeed, that the technology is real and does what we’ve been saying it can do. We’ve been at this a while — we started working on solid-state batteries back when everybody was excited about lithium-ion.

We began with a solid-state battery technology for microbatteries from Oak Ridge National Lab, and when I did the analysis there, I realized that those batteries could hold a lot more energy than lithium-ion could. But you could only make those batteries with a very expensive, slow process. And you can only make microbatteries — very small cells. So over the years, we’ve been investigating, researching, trialing — we’ve just about flipped over every rock — and we’ve developed proprietary materials that nobody else has. But it’s taken that to really come up with a solution.

Munsell: And what makes your technology unique among those handful of companies making actual solid-state batteries?

Johnson: There is one other company that I’m aware of that is working with glass, but they’re not doing what we’re doing. Our glass is a separated coating on the cathode, but it also extends into the cathode. So we actually have a very fast, straightforward manufacturing technique that allows us to bond a battery to the cathode and separator in a single step. It’s pretty cool.

Munsell: So what does your go-to-market plan look like at this point? You said you were working on getting out of the lab — what are the next steps?

Johnson: We’re talking to investors now — basically, to start gearing up so we can actually put together a prototype, or demonstration manufacturing line, or however you want to describe it. But right now, the cells are being made in a laboratory by Ph.D.-level scientists by hand, as you would expect. But we’re starting to get some more sophisticated assembly fixtures so that we can — I wouldn’t say automate, but semi-automate, actually have some tools that will allow us to produce consistent yield.

Munsell: Shifting gears a bit — as someone who has been working in science and energy for so long, how has climate change influenced your work?

Johnson: Climate change has been my primary motivator. It’s been frustrating that scientists have been aware of the need to address climate change for, geez, many years, going back to the mid-1970s, maybe even sooner. But the politicians and decision-makers have, until now, not seen the need to address the problem. Now it’s beginning to overwhelm us in terms of the weather patterns that we see. And so everybody, all of a sudden, is just starting to do something about it. I’m happy that it’s finally happening. Hopefully, it’s not too late.

Munsell: And that leads me to my next question: As a prolific inventor, someone who has created so much and is still creating, how does that impact your outlook for our future when it comes to climate?

Johnson: Well, we’ll deal with it. When I talk to kids, I tell them that human beings are built to be problem-solvers; it’s what we do best. The impact on humanity remains to be seen. When I say, I hope it’s not too late, I’m saying that knowing that the CO2 levels have gotten to a point where we’re in a no man’s land, and we don’t know what the implications are going to be; the Earth is a large ecosystem. And the ultimate response, I think, remains to be seen. I think there’s a lag in terms of how long the warming cycle will last before it turns around and starts to cool again.

It’s like turning a rudder on a ship — you can turn the rudder and the ship will start to turn, but it’s gonna go a long way before you get going in a new direction. So we’re turning the rudder. But what will it take before we actually change the path that we’re on, and we start to see the climate begin settling down? We’ll see.

Mike Munsell: What advice do you have for Canary’s audience, many of whom are renewable energy and climatetech professionals?

Johnson: Well, climate change is an important problem to address; it’s probably the most important challenge humanity has faced. It could literally lead to our demise. So I would encourage anyone who has technical interest, and even social interest, because there are a lot of people that need to understand the implications of what we’re facing. There’s a role for everyone to play in addressing this challenge and getting the resources and problem-solving momentum that we will need to move things in the right direction.

Munsell: Are there any new technologies out there that excite you from a decarbonization or renewable-energy point of view?

Johnson: Yes, my next invention that I haven’t talked to you about! I’m working on a project that condenses water from the ambient air. Most of the water-stressed areas around the world have adequate humidity in the air to make the technology work. So I’m looking at how to do that cost-effectively.